Impact Starts with Intelligence

Worldly delivers real data specific to your supply chain, products, and operations.

Worldly delivers real data specific to your supply chain, products, and operations.

Built by industry experts and relied on by market-leading brands and manufacturers, Worldly provides your business with the insights needed for impact improvement, compliance, and disclosure.

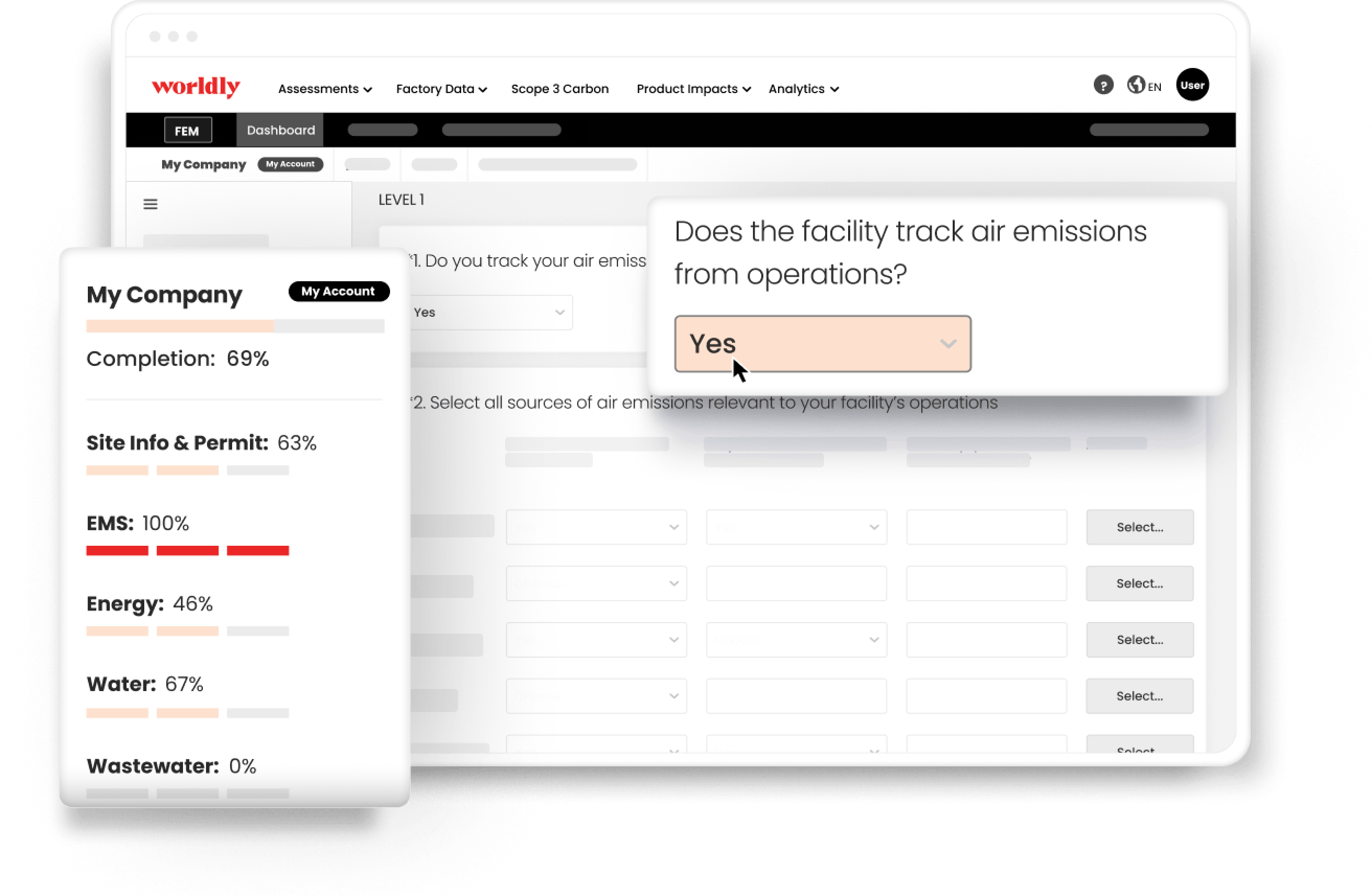

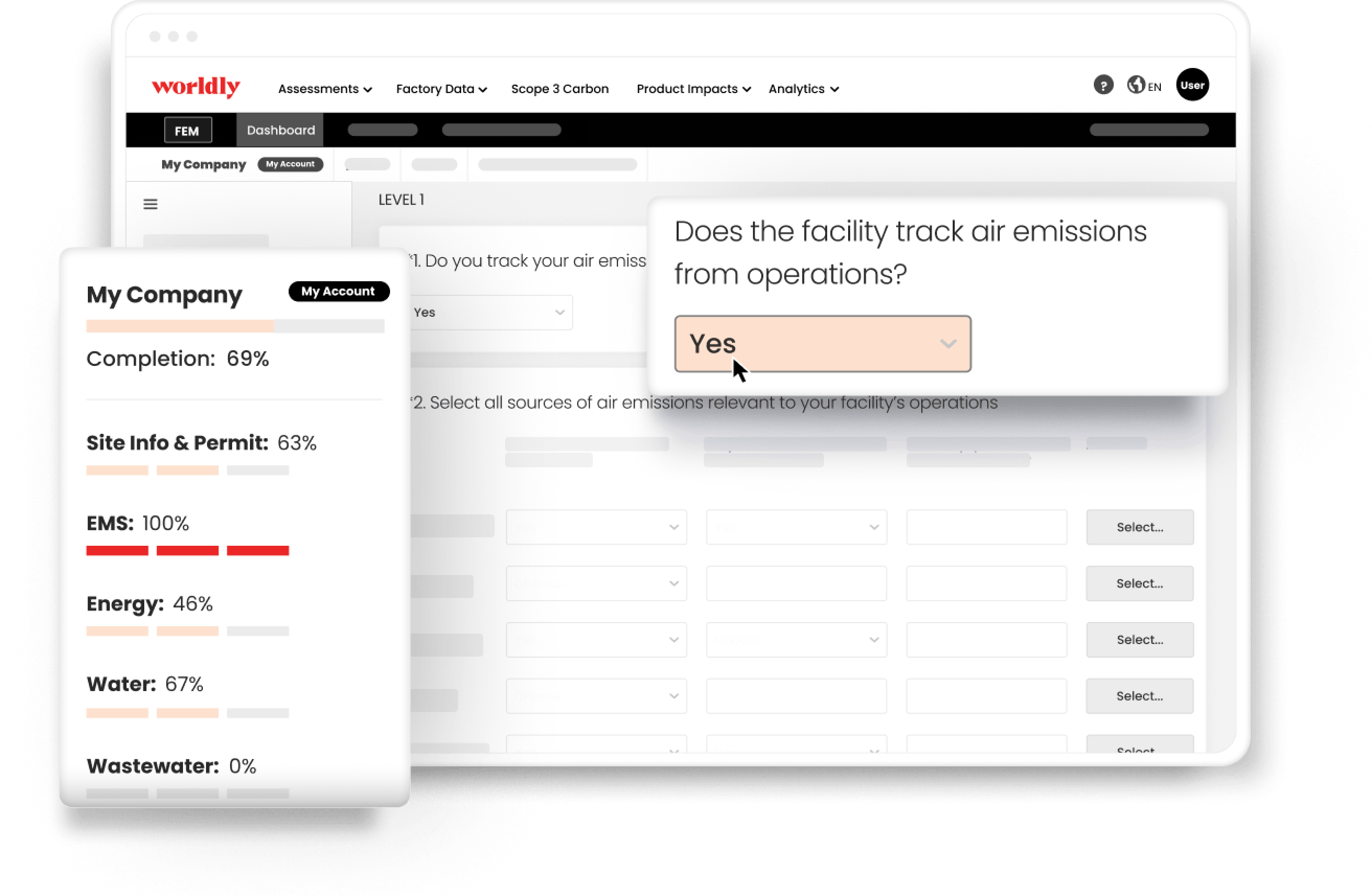

With standardized environmental and social assessments such as the Higg Index FEM, FSLM, and BRM.

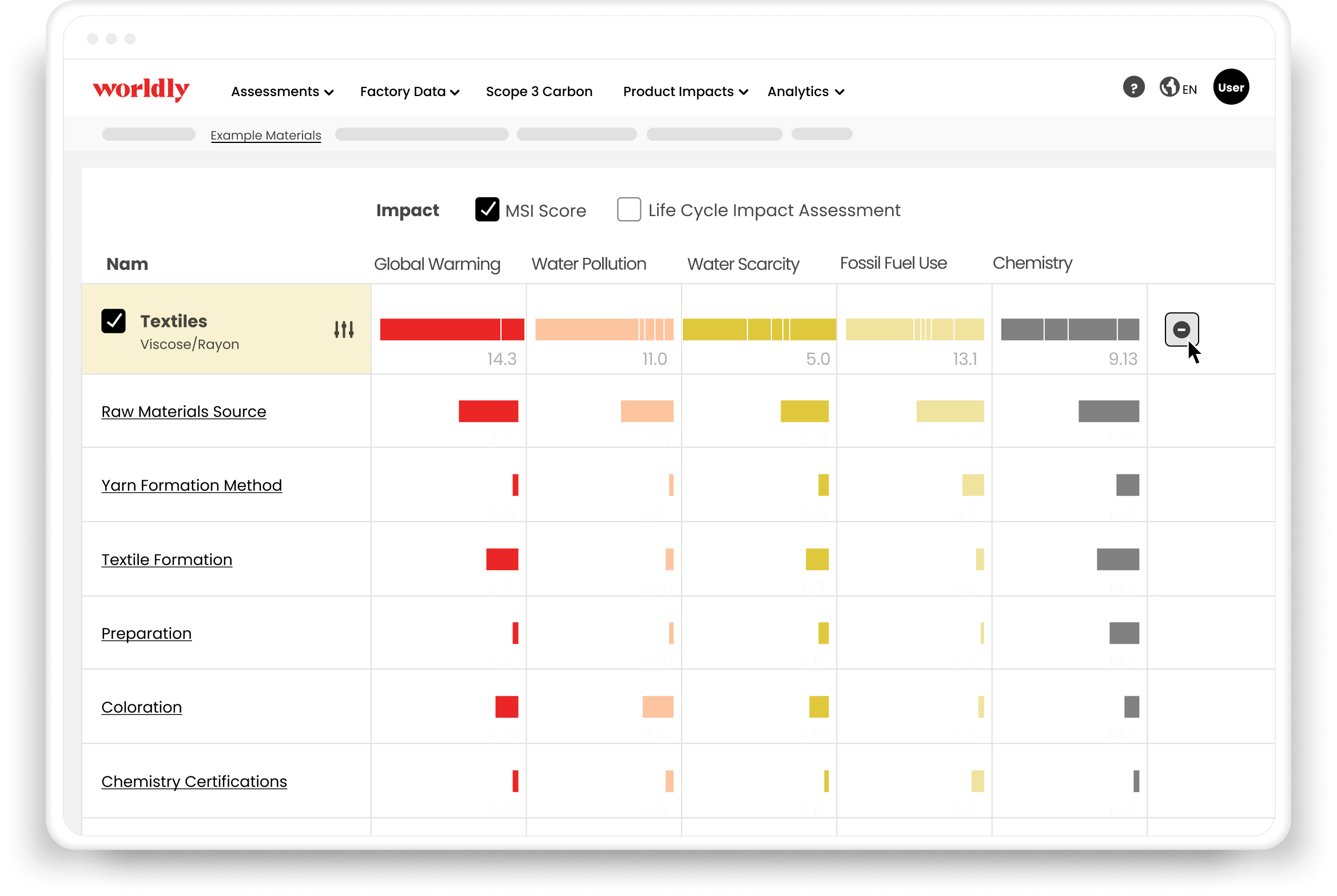

From material selection to end of use, across carbon, water, and more. Understand your products and supply chain at the resolution you need.

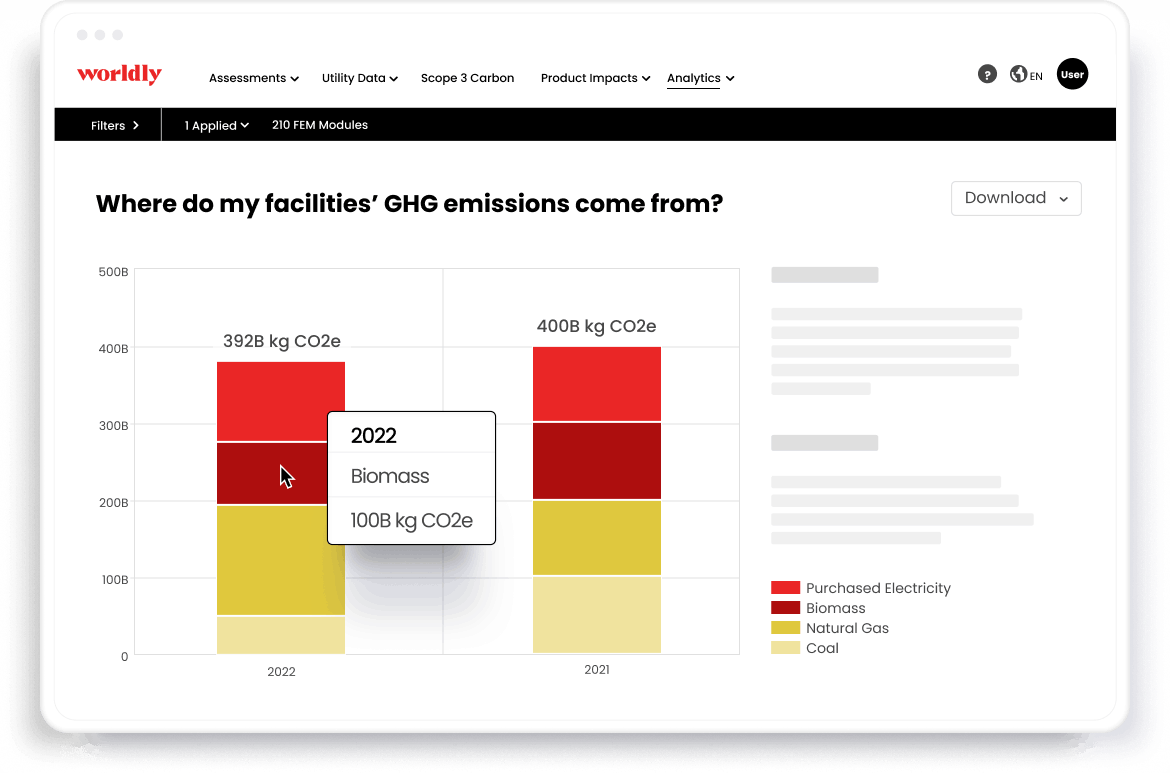

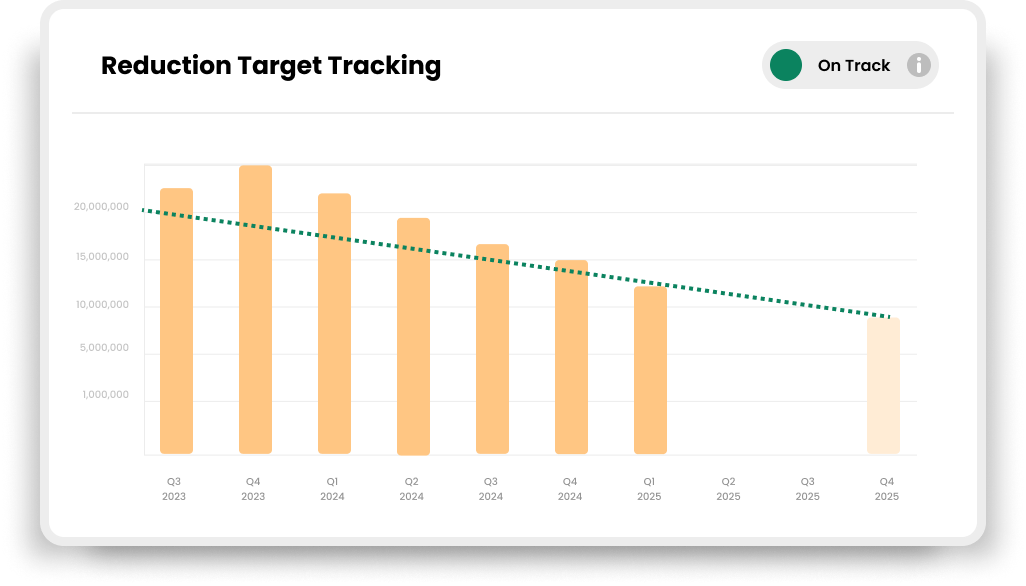

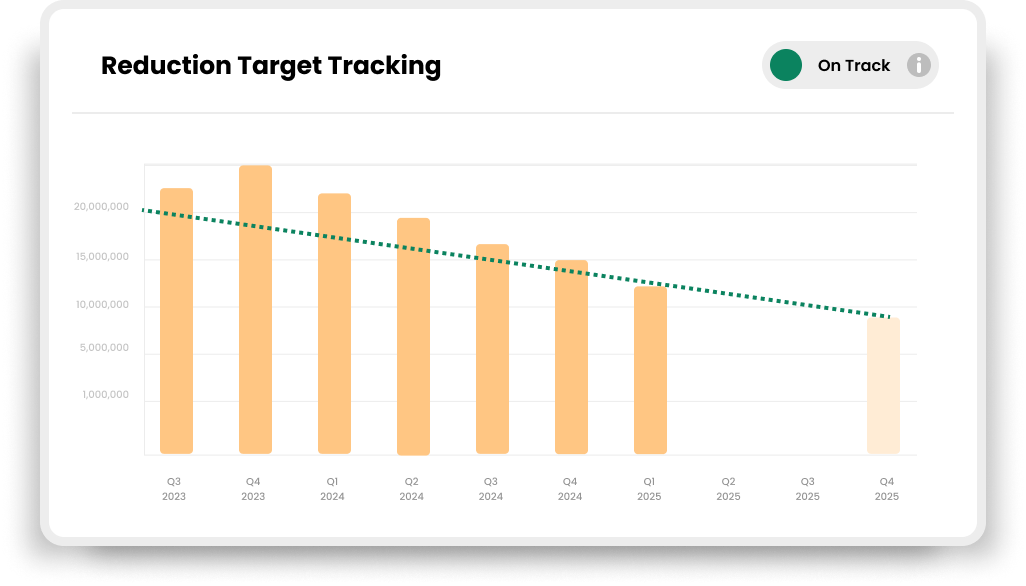

Automate the busywork: Our dashboards provide easy-to-read graphs that help you understand your progress, identify opportunities to improve, and take corrective action to help you comply with corporate disclosure and regulatory requirements.

Worldly has helped us narrow our focus on finding more sustainable materials across the company. We learned that even though we had sustainability programs in place, we could still do better.

Worldly helped Hydro Flask better align with our suppliers while also building trust. We gained more visibility into our global supply chain, and identified areas to improve social and environmental performance.

As we work towards climate-positive, Worldly will be the main tool to help us track our reduction targets.

It was easy to select Worldly. Our customers were asking us to report our data using the platform, so we knew joining would not only help us manage ESG impact, but also streamline communication to clients.

of shoppers want to know about the sustainability of products they purchase.*

of carbon emissions come from consumer goods and their supply chains.*

Everything you need to optimize, intervene on, and achieve reduction goals

With features to collect year-round data, spot areas to improve, and track targets, Worldly streamlines your SBTi Scope 3 emission reductions goals tracking.

© 2024 Worldly. All Rights Reserved